Maillard reaction enhances flavor, aroma, color, and texture while boosting consumer appeal.

I have spent years working in food labs and commercial kitchens studying how heat changes food. I know the science and the practical moves that turn raw ingredients into craveable products. This article explains what are the advantages of Maillard reaction in food processing. You will get clear facts, simple controls, real examples, and tips from hands-on experience to help you use this powerful reaction safely and effectively.

What is the Maillard reaction and why it matters

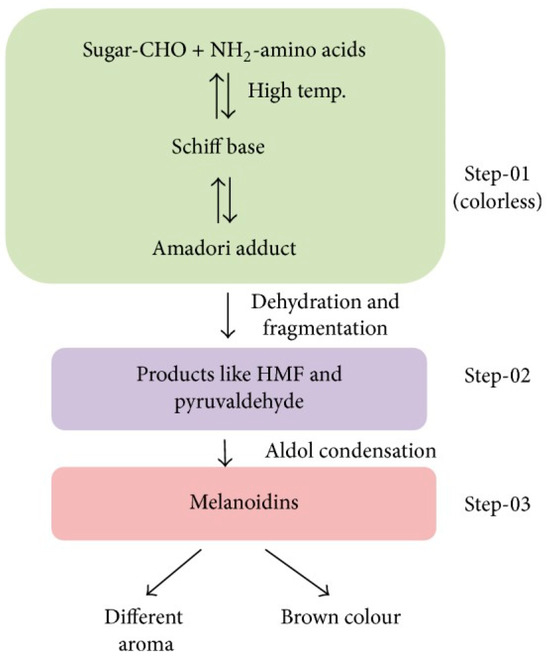

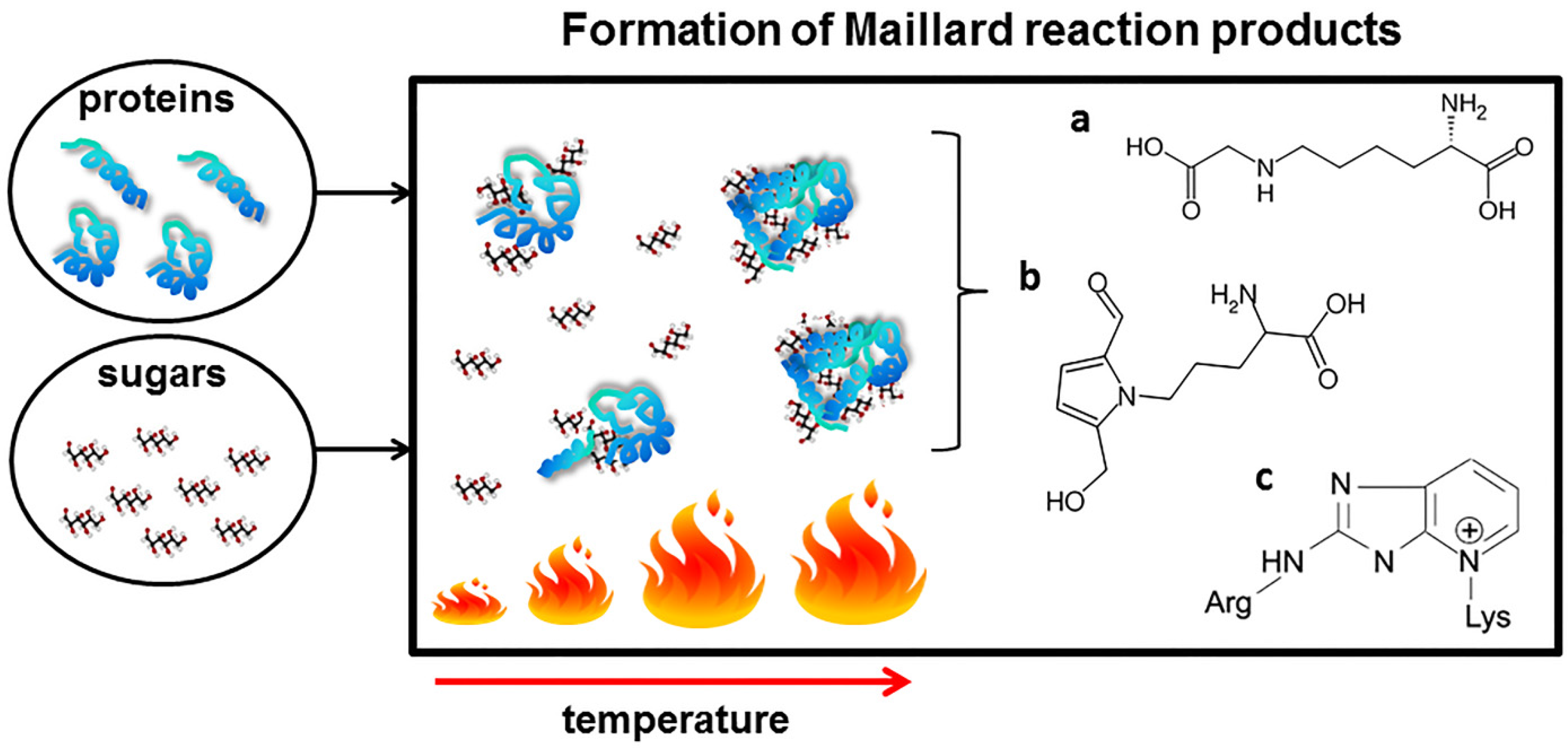

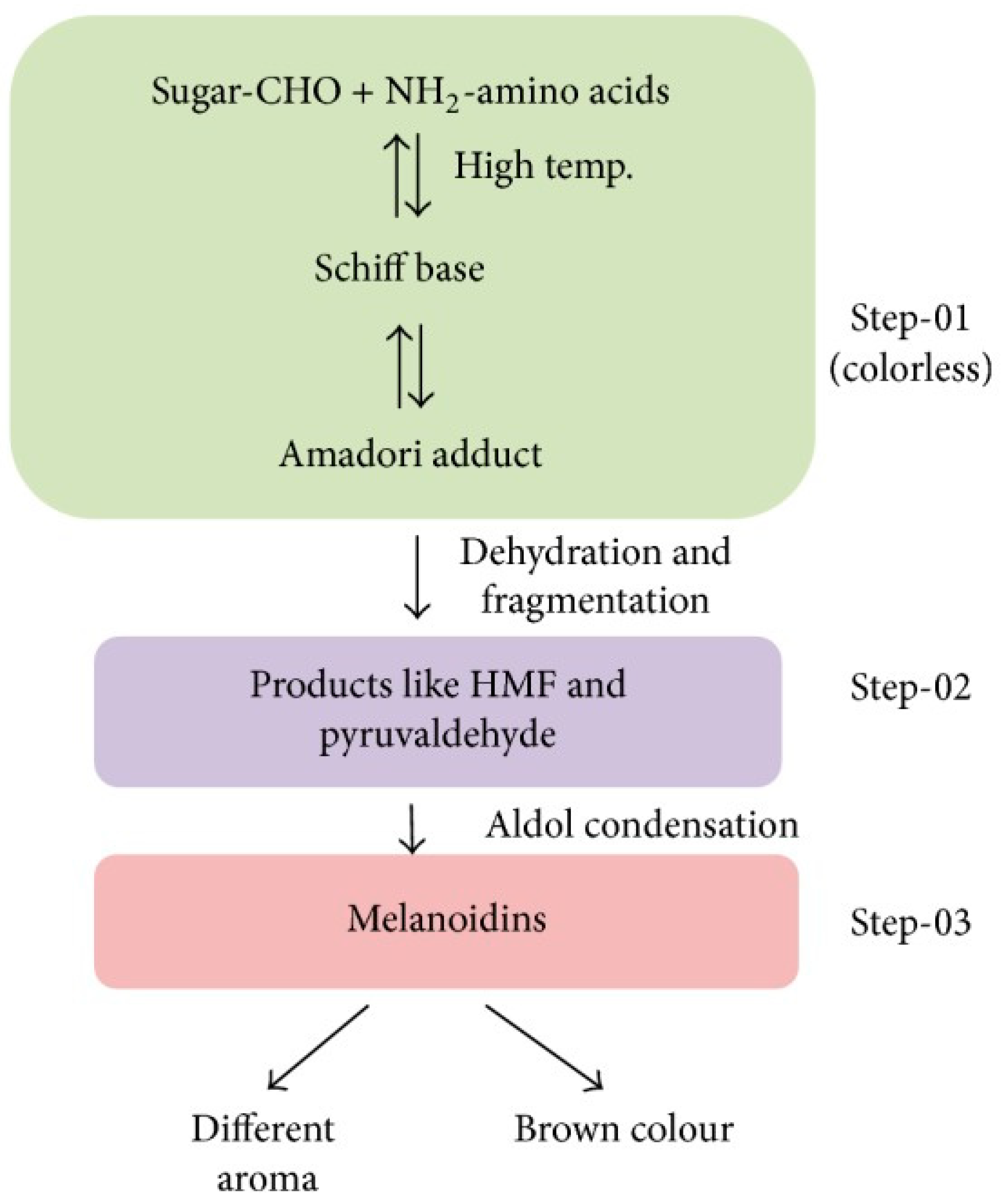

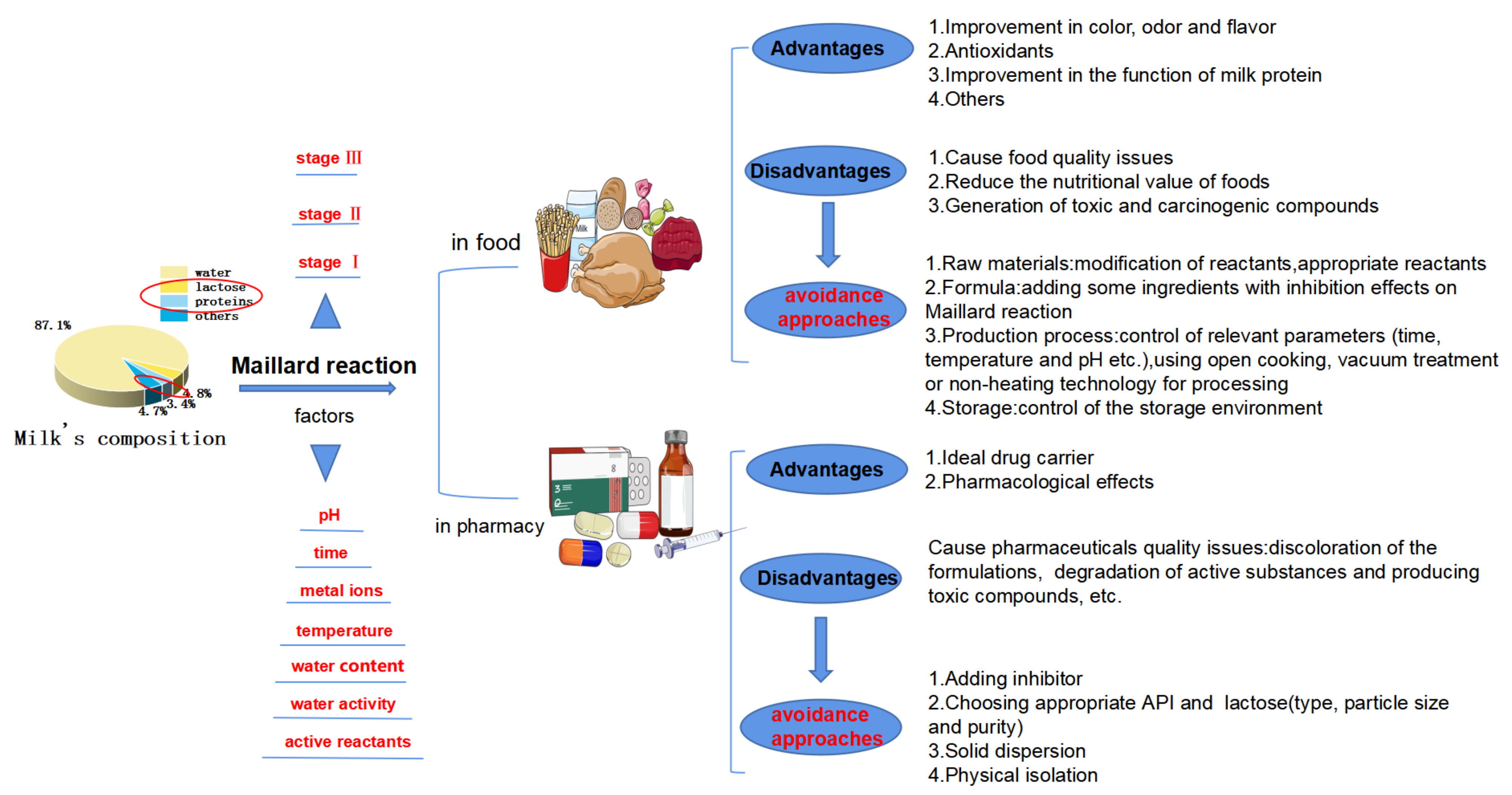

The Maillard reaction is a chemical change between reducing sugars and amino acids. It happens when food is heated and produces brown pigments, flavors, and aromas. This reaction is different from caramelization because it needs amino acids. Understanding what are the advantages of Maillard reaction in food processing lets you shape product flavor, look, and texture on purpose.

Core advantages of Maillard reaction in food processing

The Maillard reaction gives many benefits that food processors value. Each benefit helps make better products and stronger brands.

-

Flavor and aroma enhancement

The Maillard reaction creates complex taste and smell compounds. These compounds add roasted, nutty, meaty, and toasty notes. When you target these notes, product appeal rises. This is a central reason manufacturers focus on what are the advantages of Maillard reaction in food processing. -

Color and visual appeal

Golden crusts and brown glazes come from the Maillard reaction. Color improves perceived doneness and quality. Great color boosts shelf presence and buying decisions. -

Texture development

Maillard browning helps form crispy crusts and firm surfaces. It also builds mouthfeel by changing surface proteins and sugars. Controlling it lets you tune chew, crunch, and tenderness. -

Aroma retention and shelf perception

The reaction creates volatile aromatics that persist after cooking. These aromatics make packaged or ready-to-eat foods more attractive at first sniff. That helps with repeat purchases. -

Increased perceived freshness and quality

Browning signals proper cooking to consumers. Products that use Maillard browning often rate higher on quality in sensory tests. This is a key strategic advantage for brands. -

Functional changes to ingredients

The reaction can produce compounds that increase water binding or change emulsification. These changes can improve dough behavior, snack expansion, and coating adhesion. -

Product differentiation and innovation

Mastering the Maillard reaction enables unique flavors and textures. That supports product lines like artisanal breads, specialty snacks, and roasted plant-based proteins. Knowing what are the advantages of Maillard reaction in food processing helps R&D teams innovate without guessing.

How processors control the Maillard reaction for consistent results

Controlling this reaction yields predictable benefits and avoids problems. Here are practical levers you can use.

-

Temperature and time

Higher heat speeds the reaction. Short, hot bursts build surface color fast. Lower heat gives milder browning. Test time and temp together to match desired flavor and color. -

Water activity and moisture management

The reaction is fastest at intermediate moisture levels. Very wet or very dry conditions slow it. Adjust baking humidity, drying steps, or glaze water to tune browning. -

pH control

Higher pH accelerates the Maillard reaction. Bakers add small amounts of alkaline ingredients to deepen crust color. Use pH changes carefully to avoid off-flavors. -

Sugar and amino acid levels

Increasing reducing sugars or free amino acids increases browning and aroma. Ingredient selection matters. Enzymes like amylases can free sugars in dough to boost crust color. -

Surface treatments and coatings

Brushing with milk, egg wash, or syrup changes surface chemistry and enhances browning. These simple steps can amplify the advantages of Maillard reaction in food processing. -

Time staging and equipment choices

Use staged heating or specialized ovens to control surface and core reactions. Conveyor ovens, steam injectors, and infrared heaters give different browning profiles.

From my lab trials, small shifts in moisture and pH had the biggest practical payoff. Start with one variable at a time. Keep records. Replicate at scale before launching.

Practical examples: where Maillard reaction adds value

Seeing real examples makes theory useful. Here are common products and how they benefit.

-

Bread and baked goods

Crust color, caramelized notes, and crisp texture are all Maillard-driven. Adjusting sugar and baking time made a small bakery product taste richer with no extra fat. -

Roasted coffee and cocoa

The deep roast flavors and aromas come largely from Maillard chemistry. Roast curve control gives signature flavor profiles. -

Meats and plant-based proteins

Browning creates savory, umami-like compounds. For plant proteins, controlled Maillard can mask beany notes and improve meaty character. -

Snacks and cereals

Color and aroma from Maillard reaction increase snack desirability. Light roasting of grains improved shelf appeal in a project I led. -

Sauces, broths, and gravies

Concentrated Maillard flavors add depth. Slow browning and reduction create rich bases for soups and ready meals.

These examples show how knowing what are the advantages of Maillard reaction in food processing leads to targeted, marketable improvements.

Risks, trade-offs, and safe strategies

The Maillard reaction is powerful but not without downsides. Knowing limits keeps products safe and compliant.

-

Formation of unwanted compounds

High heat can create acrylamide and other processing contaminants. Monitor temperatures and use lower-temperature strategies when possible. -

Nutritional changes

Some amino acids and vitamins can degrade during intense browning. Balance flavor goals with nutritional targets. -

Bitterness and burnt flavors

Overcooking causes harsh notes. Stop browning at the desired sensory point. Use pilot-scale runs to find that point. -

Color variability and scale-up issues

Small changes in equipment or batch size can change browning. Standardize procedures and use in-line controls like surface temperature sensors.

Mitigation tips I use in product trials:

- Lower peak temperature and extend time when safe.

- Add asparaginase in some formulations to reduce acrylamide risk.

- Use antioxidants to preserve desirable aroma compounds.

- Track moisture and surface temp during scale-up.

These steps keep the advantages of Maillard reaction in food processing while reducing harm.

Economic and sensory impact for businesses

Leveraging Maillard benefits can boost sales and lower costs.

-

Higher product appeal often means higher price points.

Better flavor and color increase perceived value. That helps with premium positioning. -

Improved shelf perception supports retail success.

Browning that signals freshness can improve sell-through. -

Process efficiency gains

Using targeted browning can reduce the need for added flavors or colorants. That lowers ingredient costs. -

Competitive differentiation

Signature roast profiles or crusts help products stand out. Documented advantage builds brand stories.

In my experience, a modest investment in oven controls and formulation tweaks returned multiple times that cost through better sensory scores and higher shelf velocity. Knowing what are the advantages of Maillard reaction in food processing helps justify the investment.

Best practices checklist for applying Maillard reaction

Use this quick checklist when developing or refining products.

- Define the target flavor, aroma, color, and texture.

- Run small pilot trials adjusting only one variable at a time.

- Monitor surface temperature and moisture during processing.

- Consider pH and ingredient adjustments to accelerate or slow browning.

- Test for contaminants like acrylamide when using high heat.

- Scale up gradually and document changes to equipment or batch size.

- Use sensory panels to confirm consumer preference before launch.

Following these steps helps you capture the advantages of Maillard reaction in food processing without surprises.

Frequently Asked Questions of what are the advantages of maillard reaction in food processing

What exactly does the Maillard reaction do to food flavor?

The Maillard reaction forms many small molecules that create roasted, nutty, and savory flavors. These compounds come from reactions between sugars and amino acids during heating.

Is Maillard reaction the same as caramelization?

No. Caramelization is sugar-only browning. Maillard needs sugars and amino acids, so it produces more complex aromas and brown pigments.

Can Maillard reaction be controlled in large-scale production?

Yes. Control comes from managing temperature, time, moisture, and pH. Good equipment and pilot testing make results consistent at scale.

Does Maillard reaction affect nutrition?

It can. Some amino acids and vitamins reduce during intense browning. Balance sensory goals with nutrition and test nutrient levels.

Are there safety concerns with Maillard reaction?

High-temperature Maillard can form compounds like acrylamide. Using lower peak temperatures, enzyme treatments, and proper controls reduces risk.

How can small bakeries improve Maillard browning without new equipment?

Simple moves like adjusting dough sugar, using an egg wash, tweaking oven humidity, or slightly raising pH can deepen color and flavor.

Will Maillard reaction mask off-flavors in plant proteins?

Yes. Controlled Maillard browning can add savory notes and reduce beany off-flavors. It works best when paired with flavor masking strategies.

Conclusion

The Maillard reaction is one of the most useful tools in food processing. It delivers flavor, aroma, color, texture, and market value when used with care. By controlling temperature, moisture, pH, and ingredients, you can harness what are the advantages of Maillard reaction in food processing while minimizing risks. Try small, documented trials, and use sensory feedback to guide scale-up. If you want tastier, more appealing products, start testing controlled Maillard steps today. Share your results, subscribe for more practical guides, or leave a comment with a product you want to improve.